DM Studio System 2

With a simplified, two-step process, the Studio System 2 is the easiest way to print complex, high-quality metal parts in your office.

Presentation

- Designed for the office — The Studio System 2 was designed from the ground-up to fit into your team’s workflow. With no solvents, no loose metal powders or lasers and very little operator intervention required, the system makes it easy to start printing metal parts – no third party equipment or special facilities required.

- Easy, two-step processing Making complex, high-performance metal parts has never been easier. Featuring a breakthrough two-step process, next generation Separable Supports™, and a software-controlled workflow, the Studio System 2 makes it simpler than ever to produce custom metal parts.¹

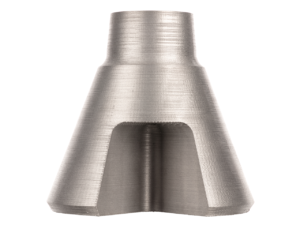

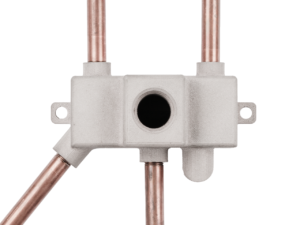

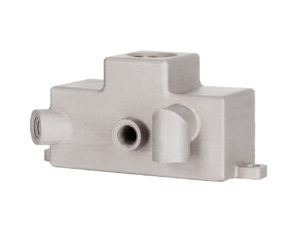

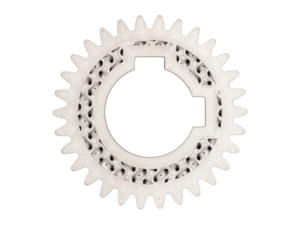

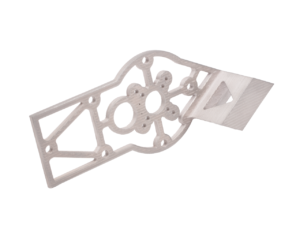

- High-quality partss: Easily produce difficult-to-machine parts featuring complex geometry like undercuts and internal channels. Fabricate®, the software at the heart of the Studio System, automates complicated metallurgical processes to produce high-quality parts with densities and feature accuracy similar to casting.PA6

Printer Spec

The printer was designed from the ground-up for simple installation and use. Its process is similar to the safest, most widely used 3D printing process—Fused Filament Fabrication (FFF).

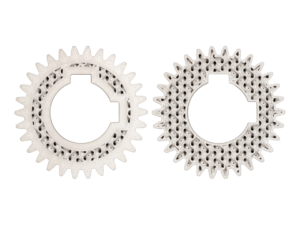

Unlike laser-based systems that selectively melt metal powder, the Studio System™ 2 printer extrudes bound metal rods, eliminating requirements associated with metal 3D printing and enabling new features like gyroid infill for lightweight strength.

Furnace Spec

Fully-automated and sized to fit through a doorway, the furnace delivers industrial-strength sintering in a form factor suitable for shop environments. With high thermal uniformity and low gas usage, the furnace heats parts in a vacuum-enabled chamber to just below their melting point, fusing the metal particles together to create sintered parts with densities up to 98%.

Featuring an external gas hookup and adjustable shelving totaling 3,000 cm2 of surface area for sintering parts, the furnace scales to support mid-volume production of highquality, dense metal parts ready for end-use applications.